Which parts do you need?

- Bi-metal heatbreak/titanium heatbreak for Prusa Mini (+)

- Allen Key,1,5mm and 2.5mm

- Adjustable wrench

- Open-end wrench/nozzle removal tool (for the nozzle)

Instructions

Here are step by step instructions for the installation of the upgrade. These instructions can be used for both the bi-metal and titanium heatbreaks.

Step 1

- Remove the silicone sock, if you have one.

Step 2

- Preheat the Hotend.

- Unload the filament.

- Remove the nozzle.

Step 3

- Remove the screw shown in the first picture.

- Loosen the cable clip (green arrow).

- Remove the 2 screws shown in the 3rd picture.

- Remove the MINDA/SUPERPINDA holder, to be able to move the heatblock.

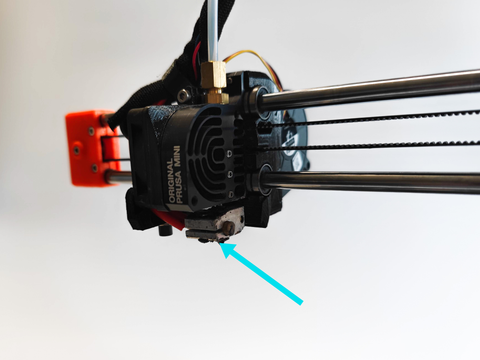

Step 4

- Untighten the 3 screws shown in the picture. (You can leave them in there to avoid loosing them.)

- Pull the heatblock and heatbreak down.

Step 5

- Make sure that the hotend is still pre-heated.

- Carefully remove the old heatbreak.

- Insert the new heatbreak, and spread the included thermal paste around it.

Step 6

1. Untighten the PTFE coupler

Step 7

- Put the included PTFE tube in the heatbreak.

- Insert the heatbreak back into the heatsink (make sure the thicker part is flush with the bottom of the heatsink).

- Tighten the grubscrews, while putting upwards pressure on the heatblock.

- Wipe of all excess thermal paste.

- Insert the nozzle.

Step 8

- Tighten the PTFE coupler.

Step 9

- Put the cable clip back in place and tighten the screw

- Put the MINDA/SUPERPINDA holder back, and tighten the screws.

Step 10

1. Calibrate the first layer again, it may be necessary to adjust the MINDA/SUPERPINDA's height

And... You've finished!

1 thought on “Prusa Mini (+) heatbreak upgrade guide”

Frederic Heise

Hi, are there any Gcode changes for this upgrade as there is one for the Binstech?